Meeting the Needs of Our Changing Industry

Reprinted from Wall & Ceilings

Since 1969 Miami-based Plastic Components has been the leading manufacturer of trims and accessories for the drywall, stucco and EIFS industries. Our products meet or exceed ASTM standards and local building codes, and are listed by Warnock Hersey/Intertek for compliance to ASTM. We are also active members of many trade associations and standards committees.

As the needs of our industry evolve, we develop products to help meet these needs. One such product line launched a few years back was colored trims for stone veneer to match veneer masonry.

Plastic Components offers white, gray, tan and dark brown foundation sill screeds, casing beads and drip edges for stone veneer applications. Available in 10′ lengths, our color trims eliminate painting, saving time and money, and delivering better job quality. The colorant is molded into the trim so there’s no chipping or loss of color. These trims meet ASTM standards D1784, C1063, D4216 and C1780.

Another product innovation from Plastic Components is our Ultra-Lath Plus non-rusting lath for stucco applications. We were part of the team that developed the three-part ASTM standard for non-metallic lath. Ultra-Lath Plus passed the NFPA 285 fire test and has third-party certification through IAPMO. And last year it obtained Florida Building Code FBC approvals.

Ultra-Lath Plus is available in rolls, sheets, with and without paper backing, and Strip-Lath Plus strips.

In recent years we have seen increased interest in two areas with regard to exterior walls. One is moisture management—how to move moisture away from the wall. The second is continuous insulation. CI is the result of the U.S. Department of Energy’s interest in reducing energy consumption in our structures. Since 2012 there has been a continued push to move away from interior batt insulation to a continuous or unbroken layer of insulation on the exterior of buildings. Plastic Components responded to market demands in the following ways:

Moisture Management

Plastic Components has always offered moisture management products for both EIFS and stucco applications. As the requirements have become stricter, we have developed and continue to develop new products to meet these needs.

Ultra Drain Mat is an entangled mesh rain screen system that, when installed in the wall assembly, allows for drainage and cross-drying within the cavity. These are two critical issues for managing moisture. The product comes in 39″ x 61.5′ rolls, 0.25″ thick. There is also a 0.40″ thick version.

Flashing products. We have always offered drip edges and weep screeds for moisture management. Just recently we rolled out our Ultra Casing bead, a casing bead with a built-in moisture flange. It not only removes a step in the installation of trims—by removing the need for backer rod—but also provides an improved seal around all window and door openings. Available in several colors including white, tan, gray and dark brown, the colored casing beads are part of the stone veneer trim line mentioned earlier.

Continuous insulation. Plastic Components has provided solutions for exterior insulation with our EIFS products, also known as the original CI, since the 1970s. These products include a wide assortment of starter tracs and include the STDE, SB, CB and UDT series. We are the only manufacturer to offer these tracs in thicknesses from 1/2″ all the way up to 4″.

Hard Coat Stucco Solutions

We believe that no one product or system is right for every application, so when we started receiving more and more interest in a hard coat stucco solution for CI, also known as CI Stucco, we began developing trims to meet this latest need.

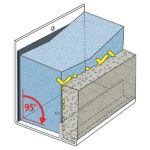

The STCI is a starter trac that we like to say got together with a casing bead to create a new product that offers drainage protection for the foam—and a stop type of bead for finishing with cement- based stucco.

We also launched our SBCI. Its built-in corner bead is designed to finish a CI stucco system around windows and doors.

Always innovating. Always listening to our customers. That’s our mission at Plastic Components, Inc.

Herman Guevara has more than 30 years’ experience in the building materials industry, traveling world- wide, living at times in Mexico, Argentina and Puerto Rico. He serves on many industry boards and committees including AWCI, FWCCA, SMA and ASTM. He holds a bachelor’s degree in business administration (University of Michigan) and a master’s degree in international management from AGSIM (Thunderbird).